Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

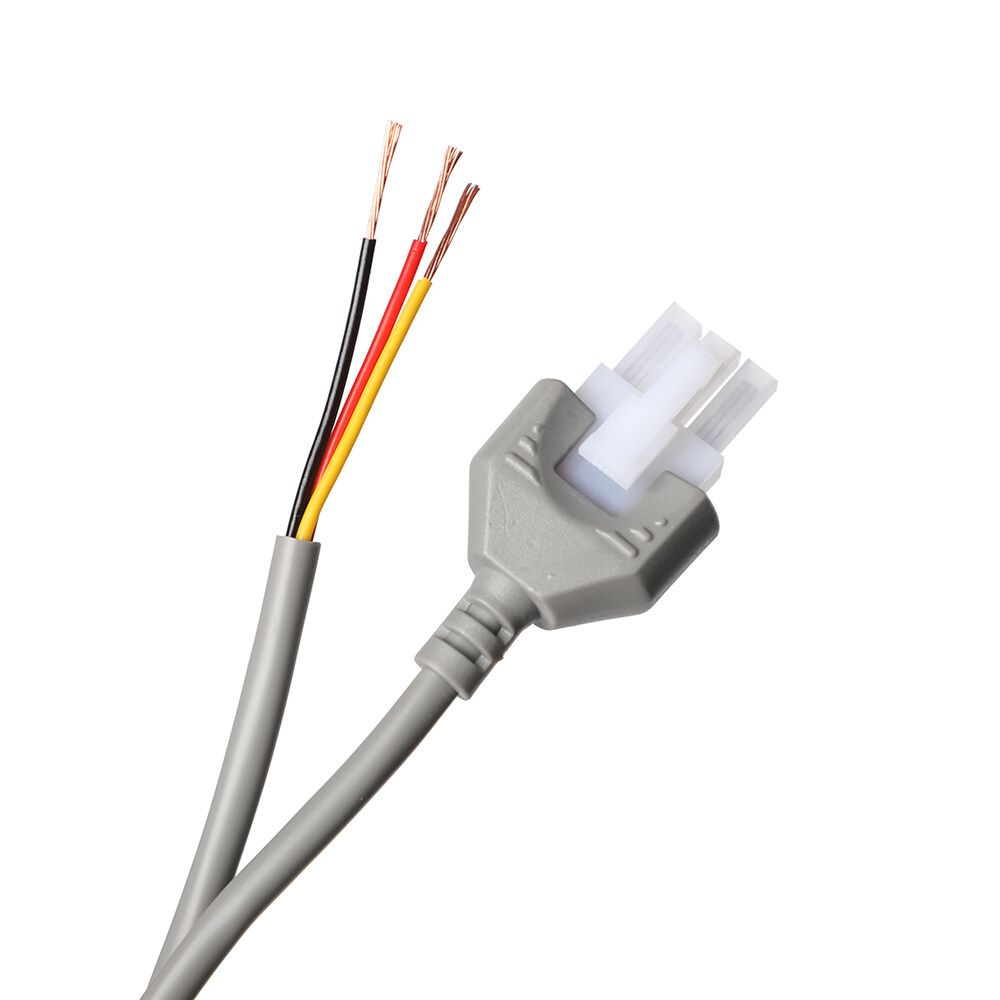

Wiring Harness Assembly

Wiring harness assembly is the process of bundling wires and cables together in a systematic manner to create a single, organized unit. This unit is then used to connect various electrical components in a piece of equipment or machinery. Wiring harnesses are designed to be highly resilient to damage, reduce the risk of electrical faults and fires, and save manufacturing time.

Wiring harness assembly is also known as a wire harness, cable harness, cable assembly, wiring assembly, or wiring loom. A wire harness is an intricate assembly of electrical wires, cables, and connectors that transmits electrical power and information signals.

Electrical Wiring Harness Description

Wiring harness assembly, also referred to as wire harness, cable harness, cable assembly, wiring assembly, or wiring loom, is a complex process of bundling electrical wires, cables, and connectors together to transmit electrical power and information signals. This intricate assembly is designed to be highly resilient to damage, reduce the risk of electrical faults and fires, and save manufacturing time.

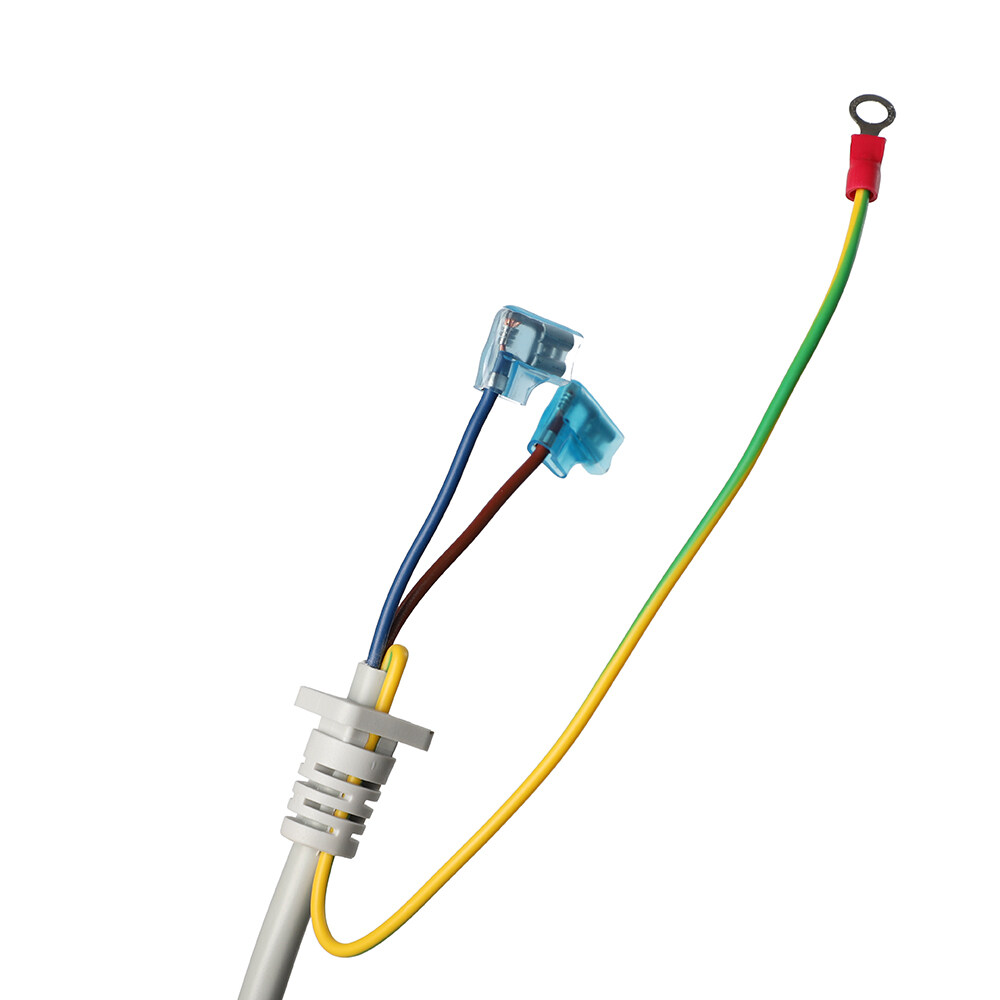

Electrical Wiring Harness Advantages

[Easy to Install]: By bundling the wires and cables together in a non-flexible manner, wiring harnesses optimize space utilization and significantly reduce the risk of electrical shorts. This also decreases installation time in production, making the process easily standardized and more efficient. The organized and systematic design of wire harness bundles ensures that the final product is not only safe but also highly functional.

[Reliable Connections]: The electrical wiring harnesses are designed with reliable connections that significantly reduce the chances of electrical shorts, voltage drops, or other problems that can arise from loose or frayed wiring. This ensures that the electrical system is stable and functions smoothly, without any interruptions or malfunctions.

[Reduced Weight & Space-saving]: Wiring harness assemblies are engineered to be lightweight and take up minimal space, making them particularly valuable in industries such as aerospace, where weight and space are critical factors. The compact design of wiring harnesses allows for more efficient use of space, reducing the overall weight of the equipment and improving its performance.

Application of Electrical Wiring Harness

·Automotive Industry: such as sensors, lights, and ignition systems.

·Aerospace Industry: such as avionics, navigation, and communication systems.

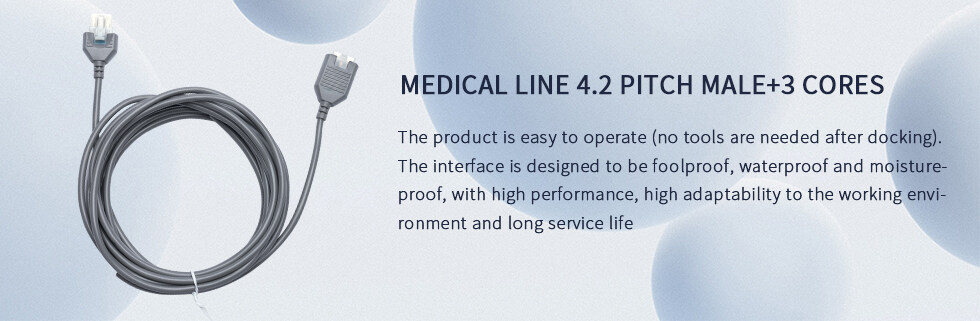

·Medical Equipment: such as MRI machines, X-ray machines, and ultrasound machines.

·Industrial Machinery: such as robots, conveyors, and assembly lines.

·Consumer Electronics: such as televisions, computers, and smartphones.

·Military and Defense: such as tanks, aircraft, and ships.

For more information about wiring harness assembly, please kindly contact us at any time, we are glad to answer for you. If you want to find a partner, hope that we will be your best choice.

We offer automated wire harness assemblies, if you are interested in, welcome to contact us directly.